The construction industry is adopting new digital solutions at an ever-increasing speed. It is no longer a question of whether construction companies will digitize their strategies, but when they will. New technologies have made it possible to have construction documents at the click of a button.

The interoperability between the different actors of the project facilitates the work of several professionals in a project. Technology also makes it easier for employees to work on a project and stay within the scope and budget of the project.

Most people attribute construction industry technologies to advanced heavy equipment, but beyond that are the advances we use in the office, field, and boardroom. We put a lot of resources into construction projects, and finding ways to leverage this data and increase project efficiencies is critical to ensuring a project stays on track. This article discusses some of the emerging technology trends in construction.

WHAT IS CONSTRUCTION TECHNOLOGY?

According to the Construction Industry Institute, construction technology refers to the innovative tools, software, machinery, and equipment used on a project to ensure advances in construction methods. We use construction technology in all kinds of construction projects, and the latest trends are mainly focused on prefabrication, software and green building construction.

New technologies emerge quickly, and what 20 years ago seemed like a distant technology in the construction sector, today it is implanted in construction.

According to expert, new construction companies record an average annual increase of 30% in construction technologies globally.

THE DIFFERENT TYPES OF CONSTRUCTION TECHNOLOGY

The growing demand for digitization and more innovative building construction has created a need for construction companies to develop solutions that modernize construction processes. This gives the company a competitive advantage by providing cutting-edge technology that integrates new workflow models and strategies. Below are the different types of technology used in construction.

ARTIFICIAL INTELLIGENCE (AI)

Artificial Intelligence is a technology that enables machines and computers to imitate human cognitive functions, action, and intelligence. Like most construction technologies, Artificial Intelligence is used in conjunction with other technologies such as wearables, BIM, laser scanners, and sensors for data collection and decision making. On the other hand, Machine Learning is a subset of Artificial Intelligence that uses algorithms to find repetitive patterns and make informed decisions without human intervention.

A lot of construction project data is generated over the years, and we can use artificial intelligence techniques to improve the future results of construction projects.

We can use AI to help projects in a number of ways, the main one being risk mitigation. Simulations can be made and risk factors identified. Project managers can then allocate more resources to ensure that work runs smoothly.

Project planning will be much easier. AI of the future will use a technique known as “reinforcement learning.” This technology allows AIs to learn by trial and error. Indeed, they acquire the experience of 100 years of work in a matter of minutes. Many innovations in the construction industry will come from the simultaneous learning of AI on all construction sites. The rich data collected from all the AIs will help future construction professionals to learn better. The best construction techniques will be easily shared among professionals.

Artificial Intelligence helps monitor workers and warn them of any emerging security risks. For example, if workers are not wearing their protective equipment, the AI can warn them and inform them through a wearable or smartphone. We also use AI in autonomous construction teams.

Most projects also embrace AI when it comes to project scheduling. This is because a project can be simulated numerous times and areas where adjustments may be needed for maximum efficiency and delivery. This helps keep a project on time and on budget. Artificial Intelligence also uses robots and drones to monitor the progress of a project and deliver actionable data in real time. The use of AI in construction shows improvements in the efficiency and safety of the works.

DRONES

The construction industry is rapidly adopting drones.

Drones have become a very useful instrument for making topographic maps and land surveys. Prior to their use, developers had to resort to topographic maps, which are expensive. Thanks to their ability to map large tracts of land simultaneously, drones reduce the time required and ensure the feasibility of the project.

In addition, data from drones can be used to build 3D models and help project managers spot issues that may arise during implementation. This saves costs and benefits planning.

Moving on to planning, a big headache for most project managers is how to get progress reports. Now with drones, you don’t need long emails or progress reports, just use the drone and see how far your construction team has come.

On construction crews, safety is an important part. A project manager can remotely monitor the team as they work, further increasing security. Before drones, inspections in inaccessible areas were a significant risk. Crews had to do this job, but now drones have arrived and have helped make inspections in places like dangerous rooftops now easy.

Drones do not eliminate the use of workers, but we need to train workers on how to use them correctly. The data collected by the drones can be fed into AI applications to further increase the efficiency of a project.

The ability to perform tasks remotely is a big win in the construction industry, so drone adoption should continue.

ROBOTS

Construction robots have yet to be fully embraced by the construction industry, but there are some designs on the horizon. The goal of construction robots is to address labor shortages by completely revamping construction work. The main types of robots are factory robots, collaborative robots, and autonomous robots. Factory robots are suitable for manufacturing tasks as they can efficiently perform repetitive tasks. Collaborative robots work on a construction site to perform tasks such as transporting tools. Autonomous robots can scan the environment and make independent decisions to perform complex tasks.

Many people fear that construction robots will replace construction workers. However, on the contrary, they improve the performance of the worker and reduce the wear and tear caused by years of employment.

Although robots have not been widely adopted in construction, other futuristic technologies are gaining prominence, and robots will have an impact on the construction industry in the near future. We can use robots for simple, repetitive tasks like masonry and rebar tying. Humans will continue to be present to install them in the work.

WEARABLES

Construction wearables are gaining rapid adoption in construction due to their numerous productivity benefits. The construction sector is one of the riskiest. Every year, many falls, collisions, and accidents result in deaths and injuries. Construction wearables try to solve this problem by providing workers with additional safety measures.

These construction wearables include smart boots, a smart hat, and electric gloves. Smart boots detect workers at risk of collision or fall. Electrical gloves improve a worker’s dexterity in handling tools, and smart hats help prevent head injuries.

Wearables come equipped with location trackers, biometric strain detectors, and environmental sensors. They can control repetitive movements and the likelihood of slipping and falling. Other wearables, such as glasses and smartwatches, help improve the individual safety of workers. They can track fatigue, heart rate, body temperature, and other signs that show an employee is suffering from burnout or burnout. Therefore, wearables can reduce project delays and prevent additional worker exposure to inclement weather.

Safety is always a highly discussed topic in construction, and with good reason. It is essential to adopt a proactive method to control the safety of workers. The use of wearables contributes to projects having an impact, helping stakeholders and team members to navigate safely and with fewer incidents.

3D PRINT

In traditional printing, digital designs are limited to flat printing, but in 3D printing we can use various materials to replicate a complete structure. 3D printing is also called additive technology and consists of creating a model in layers. The construction industry has not yet fully embraced 3D printing, but the potential of this new field is clear.

3D printing improves the material used in a project. We can reduce waste using 3D printing compared to traditional methods; 3D printing also increases construction speed. This is because it will be faster to replicate a building in its entirety and eliminate otherwise costly bugs.

Transparency Market research predicts that the 3D printing market will be $280Mn in 2027 from $29Mn in 2019.

The best advantage of 3D printing is material cost savings. There is very little waste. Most of the purchased material is used in the building, reducing the need for overestimation, which can be a significant cost in a project.

3D printed houses will take days to complete. This reduction in time will mean that project delivery times will be much faster. This reduces costs for construction companies.

Construction companies that adopt 3D printing will have greater brand awareness that will have a positive impact on their shareholders. Furthermore, any technology that positively affects the environment will be viewed favorably. 3D printing is such a technology.

This new technology has also reconfigured the supply of precast materials. We can print the materials for a project and transport them to the site ready for use. This speeds up the provision of materials, with the consequent saving of time and costs. Transport costs are reduced and storage costs are saved. As much as 3D technologies bring a breakthrough in construction, they face challenges in mass production. Very few 3D printers can produce on a large scale, and those that can are expensive.

Some examples of companies in the 3D printing sector are Peri group, Wasp, Apis cor and Xtree.

AUGMENTED AND VIRTUAL REALITY

Augmented Reality acts as a digital information overlay that helps visualize project information. Virtual Reality is the use of technology to simulate a new environment. Architects and contractors can now project themselves into a space and “see” what a building will look like even before the first stone has been laid. The technologies create a three-dimensional view of the finished structure.

These technologies are being adopted and used together in construction. When combined with other technologies, such as BIM, they allow for improved designs, communication, and collaboration. Architects can also easily show their projects to clients.

The benefits of AR/VR are numerous. For example, it ensures that architects, project managers, engineers, construction supervisors, foremen and technicians are on the same page. This significantly reduces inefficiencies that occur due to miscommunication.

AR/VR also enables virtual training. The first is security training, which can be delivered more easily and cheaply. There is no need to bring technicians to the job site because real hazards can be simulated.

The second is due to the reduction of costs that allows carrying out a more energetic training. This reduces security incidents and guarantees that the works are not closed due to security problems.

AR/VR tools have greatly reduced sales cycles for buildings. Potential clients can purchase off-plan properties using AR/VR. The construction sector attracts young people.

Finally, access to remote experts is essential. Engineers and architects can see the works without being physically there. Technicians will have it easier when performing tasks that require advice. Some AR/VR technologies are Daqri smart helmet, Dalux suit, Fologram, New Rochelle, and Nova.

CLOUD ESTIMATION TOOLS

Cloud estimating software is designed to accurately develop material, labor, and cost estimates for a project. There are several cloud estimation tools out there, ProEst being the most popular among them. ProEst can streamline the estimation process through collaboration and augment new capabilities relatively unavailable in traditional estimation methods.

Cloud estimating software is easier to access compared to offline estimating tools. They are easily accessible, since anyone with an Internet connection can access them from any device. On the other hand, offline estimating tools confine you within the office premises. They have better functionality, since not everyone on the design team needs all the features that come with offline estimating tools. With cloud estimating software it’s easy to turn off unnecessary devices and use only the most important ones.

There are many communication channels that can be adopted when using cloud estimation tools. Construction projects are highly fragmented, with many teams involved. Cloud estimating tools solve this gap by synchronizing the data of all team members, and these tools also allow large volumes of data to be stored online. The data can also be accessed remotely.

BUILDING INFORMATION MODELING (BIM) TECHNOLOGY

BIM technology refers to the process of creating a model of a building before it is built. Creating a model representation of a structure makes it easy to detect and eliminate risks before they occur. Using BIM also streamlines material procurement processes and overall project efficiency.

We can use BIM to eliminate the need for change orders and identify anticipated construction challenges. The interoperability of BIM software used in construction improves communication between project stakeholders by providing a centralized and up-to-date reference system. BIM is also important in post-construction building management, as it provides valuable building details that can be used to increase its life cycle.

Aside from its use as a collaboration tool, contractors use BIM technologies in prefabrication, project scheduling, quantity estimation, and collision detection. They make it easier to understand the scope of a project and any additional components that may need to be included in the cost estimate. Real-time changes to BIM models can be made, constantly updating team members with the latest information about a project.

BIM is one of the most advanced construction technologies, and it is used in collaboration with other technologies such as artificial intelligence and construction scheduling software. Data processing through AI software makes it possible to create rich as-builts and improve operations of a project after completion. In countries like the UK, BIM is mandatory on government construction projects. Due to increased demand, there are global initiatives to increase the adoption of BIM software.

As already mentioned, virtual reality makes possible the immersive visualization of the project in BIM, which leads to a greater acceptance of BIM. You can walk through a BIM model and even bring photos to the design team for review and clarification.

Some popular BIM software are Autodesk Revit, Navisworks, BIM 360, and Tekla BIMsight.

MOBILE AND CLOUD TECHNOLOGIES

Cloud technologies have been used in construction for a long time. Mobile devices now take advantage of cloud technologies and a lot of data can be shared from virtually anywhere. To stay competitive in your field, you need to have a reliable and easily accessible cloud solution. Cloud solutions are also easy for project managers to manage as they can easily access information from data analytics platforms and other connected devices. Cloud storage and data processing are some of the few advantages that we can take advantage of cloud technologies.

MODULAR, OFF-SITE AND PREFABRICATED CONSTRUCTION

Lately, a considerable percentage of construction projects are prefabrication. Prefabrication eliminates most of the inefficiencies in the work due to poor quality. One of the advantages of prefabrication is saving time. As the materials are already manufactured, the only remaining step is assembly. You can also save a lot on costs, since you can get considerable discounts on materials.

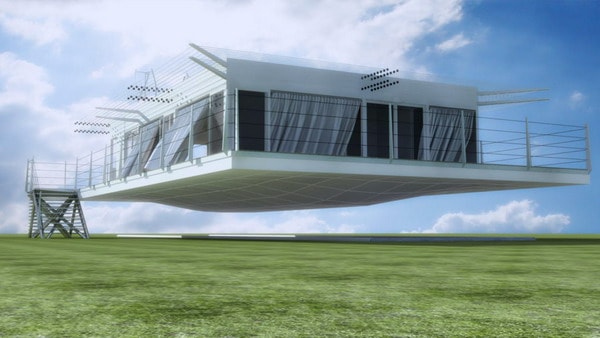

Modularization is another form of off-site construction that resembles precast construction. However, in modular construction, an entire project is prefabricated and delivered to the site. These technologies can produce buildings much faster than their traditional counterparts.

Many progressive companies are applying these strategies to improve their operations. These technologies are also ecological, since they facilitate the recycling of materials.

SELF-HEALING CONCRETE

One of the main problems with concrete is the deterioration caused by age and cracks. The development of self-healing concrete is still in its infancy, but it offers an excellent solution to concrete deterioration problems. Concrete is one of the most produced materials annually, with a production of about 4.5 billion metric tons. The key to the spoilage problem is a breakthrough.

FACIAL RECOGNITION AND BIOMETRICS

Facial recognition uses graphic information to capture various data specific to each person. This information is stored in a database where scans are matched against individuals. Facial recognition and biometrics are essential to monitor and control worker productivity. With the advancement of technology, facial recognition and biometrics can revamp project controls, payroll systems, and resource optimization. There will be great labor and cost savings.

INTERNET OF THINGS (IOT)

The IoT offers new perspectives for project teams to capture a large amount of data in real time. It incorporates software, sensors, electronic components, and network connections that enable data exchange over the Internet. IoT optimizes job site conditions and supply chain interactions. It is applied in green buildings to shut down systems when they are not needed. They can also open and close windows automatically to provide optimum light levels.

This new technology also helps predictive maintenance of buildings. Sensors can send warnings of abnormal patterns and alert workers to avoid unnecessary stops.

WHY IS IT ESSENTIAL TO CHANGE TECHNOLOGY?

Changing technologies offer an advanced way of doing things. The construction sector has made room for technologies to improve the efficiency and performance of projects. With changing technologies, higher tasks are handled, and projects that were previously difficult to execute become easier to implement and manage. These technologies ensure better organization in the construction industry by ensuring efficient use of time, capital and other resources. They offer the opportunity to create construction masterpieces.

POSITIVE CHANGES OF THE CONSTRUCTION TECHNOLOGY TRENDS

Technologies improve the productivity of any organization. In a project where the machinery is outdated, the processes are delayed and the execution is too cumbersome, leading to the waste of resources. For example, AR/VR helps engineers save time by not having to physically travel to jobsites. Your decision making is based on technology, which delivers accurate results to your inquiries.

The use of proven technologies has helped predict the success of projects and improve their reliability. Facial recognition can, for example, monitor workforce productivity and help project managers predict their remaining schedule based on computed data.

Better monitoring and evaluation is evident with the incorporation of technology. Cloud technologies will allow you to have data that project managers interpret and make decisions about.

Guarantees greater cost savings. 3D printing is a perfect example of how its use saves the construction sector the usual additional expenses in conventional forms of construction.

Most of the technology is based on offering better industrial solutions to make work easier, faster, more efficient, reliable and sustainable.

SUMMARY

Emerging technologies in construction have a positive impact. These advances seemed far off and unattainable for years, but today we can see them in use. Technology addresses inefficiencies, increases productivity and safety, and attracts younger, tech-savvy workers. To remain competitive and relevant, they have to rethink their traditional solutions to successfully manage projects. It improves operations and ensures investors the maximum return on investment.

All of the technologies mentioned are essential. We have summarized its usefulness. The key to implementing these technologies is that they save time and money, improve teamwork, and greatly increase security.

A digital strategy ensures the long-term success of a company and its projects. Investments in technology sometimes seem expensive, but a lack of investment backfires on a business.